Automatic Apple and Pear Processing Line for Juice and Puree

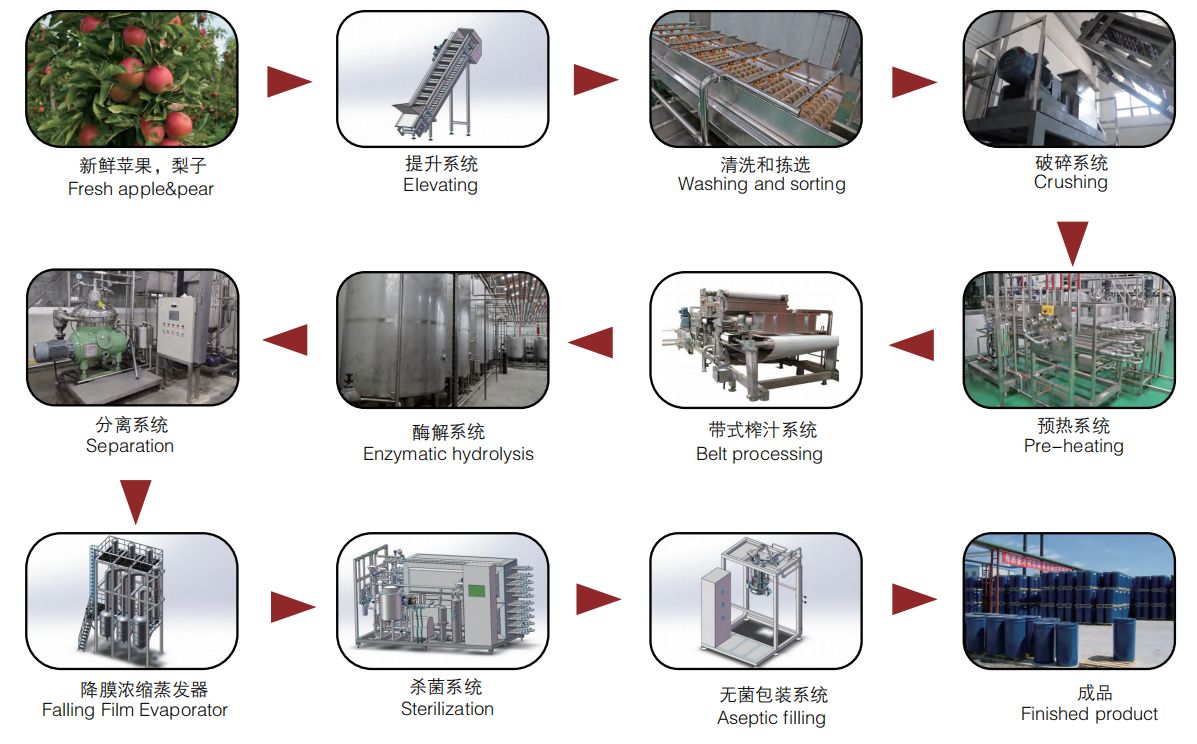

- What is the apple and pear processing production line process?

A complete apple & pear processing line includes the following sections: hydraulic convey system, scraper elevator, washing and sorting system, crushing system, pre-heating system, juice extractor or pulping machine, enzymolysis, evaporating & concentration system, sterilizing system, and aseptic bag filling system, etc.

The apple & pear juice concentrate or apple & pear puree in an aseptic bag can be further processed to juice beverages packed in tin can, plastic bottle, glass bottle, pouch, roof box, etc.

We have complete and scientific apple and pear processing technology. Through years of R&D and a mature design and R&D team, we can customize apple and pear whole-set processing line according to customer's actual needs.

EasyReal is committed to providing customers with one-stop processing production line solutions and making the best products. For supplying whole-set Apple and Pear processing line, EasyReal is the best choice!

Click [here] to consult now!

1. Main structure is SUS 304 and SUS316L stainless steel.

2. Combined Italian technology and conform to Euro-standard.

3. Special design for saving energy (energy recovery) to increase the energy utilization and greatly reduce production cost.

4. Semi-automatic and fully automatic system available for choice.

5. The end product quality is excellent.

6. High productivity, flexible production, the line can be customized depend on actual need from customers.

7. Low-temperature vacuum evaporation greatly reduces the flavor substances and nutrient losses.

8. Fully automatic PLC control fro choice to reduce the labor intensity and improve production efficiency.

9. Independent Siemens or Omron control system to monitor each processing stage. Separate control panel, PLC and human machine interface.

1. Realization of automatic control of material delivery and signal conversion.

2. High degree of automation, minimize the number of operators on the production line.

3. All electrical components are international first-class top brands, to ensure the stability and reliability of equipment operation;

4. In the process of production, man-machine interface operation is adopted. The operation and state of the equipment are completed and displayed on the touch screen.

5. The equipment adopts linkage control to automatically and intelligently respond to possible emergencies.